CLICK HERE TO WATCH THIS VIDEO

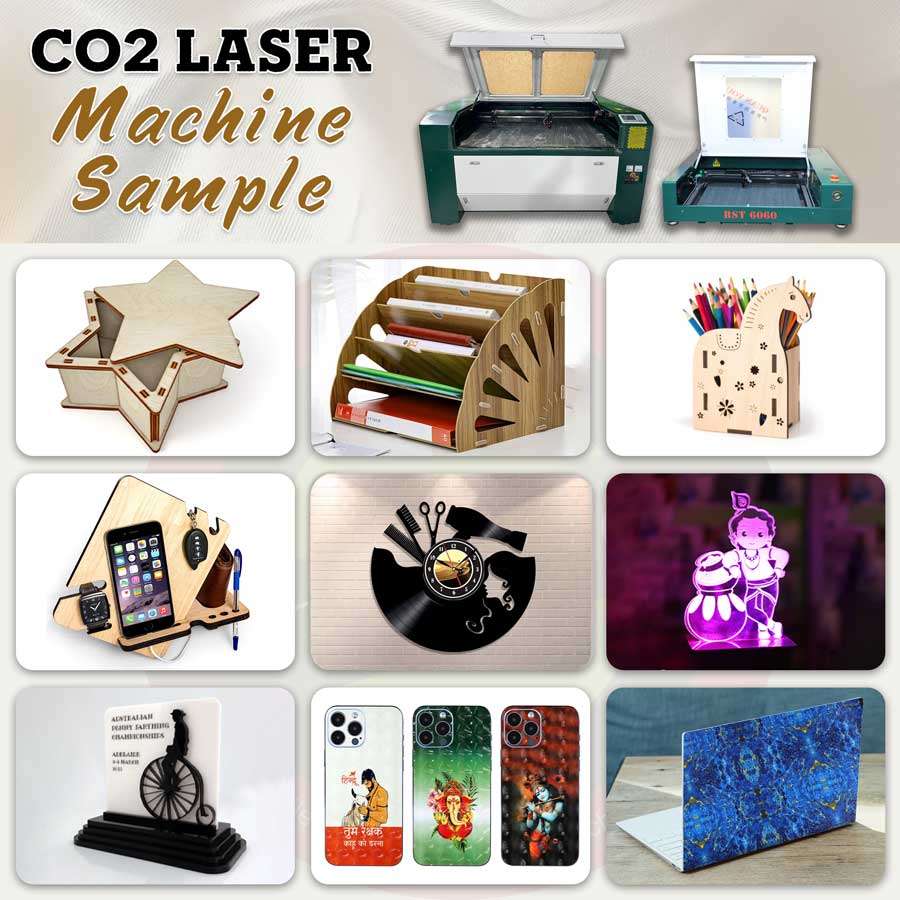

BST 6060 / 60W CO2 Laser cutting machine (CUTTING SIZE – 2ft x 2ft)

Model – BST 6060 (2’*2’)

Bed Size – 68cm x 63cm | 680mm x 630mm

Working Area – 60cm x 60cm | 600mm x 600mm

Cutting Capacity – Up to 12mm

Laser Type – Glass sealed CO2 laser

Laser Head – Black head / Golden head

Water Protection – Water cut off alarm system

Power Supply – MYJG60w AC 110v/220v

Cooling System – Water cooling

Motherboard – M3 Nano

Air Assist – Air pump (ACO-003)

Water Pump – 680B

Graphic Format – PLT, DXF, JPG, JPEG

Working Voltage – Single phase 220-230V-50-60HZ

Description: A CO2 laser cutting machine is a versatile tool used in various industries for cutting, engraving, and marking a wide range of materials, including wood, acrylic, plastic, paper, fabric, leather, and more. It works by emitting a concentrated beam of light that vaporizes or melts the material in its path, creating precise cuts or detailed engravings.

Features:

High Precision: CO2 laser machines offer exceptional precision, allowing for intricate cuts and detailed engravings with minimal margin for error.

- Versatility: They can cut and engrave a wide range of materials, making them suitable for diverse applications across industries such as manufacturing, signage, woodworking, textiles, and crafts.

- Speed: CO2 lasers can cut through materials quickly, increasing productivity and efficiency in production processes.

- Non-contact Cutting: The laser beam does not physically touch the material, minimizing the risk of damage or contamination, especially with delicate or sensitive materials.

- Customization: Users can create custom designs and patterns easily with CO2 laser cutting machines, making them ideal for personalized products and prototypes.

- Automation: Many CO2 laser machines are equipped with advanced software and automation features, allowing for precise control and customization of cutting parameters.

- Minimal Waste: The focused laser beam produces narrow kerf widths, resulting in minimal material wastage compared to traditional cutting methods.

- Safety Features: CO2 laser cutting machines are equipped with safety measures such as enclosures, interlocks, and exhaust systems to ensure safe operation and protect users from laser hazards.

There are no reviews yet.